When you’re navigating the high-stakes world of medical device development, decisions rarely revolve around convenience—they revolve around certainty. Certainty that every component functions as intended. Certainty that production partners uphold quality at a level that matches the responsibility placed on your technology. In that environment, highly specialized welding techniques and processes aren’t just technical preferences; they become strategic assets capable of influencing performance, reliability, and long-term market trust.

Table of Contents

1. Enabling Reliable Assembly of Ultra-Miniature Components

If your team works with assemblies so small they seem almost reluctant to be handled—sensor leads thinner than a hair, marker bands the size of punctuation—then you know the anxiety that comes with joining them. One slip, one extra fraction of heat, one microscopic distortion, and a component that took months to perfect suddenly underperforms.

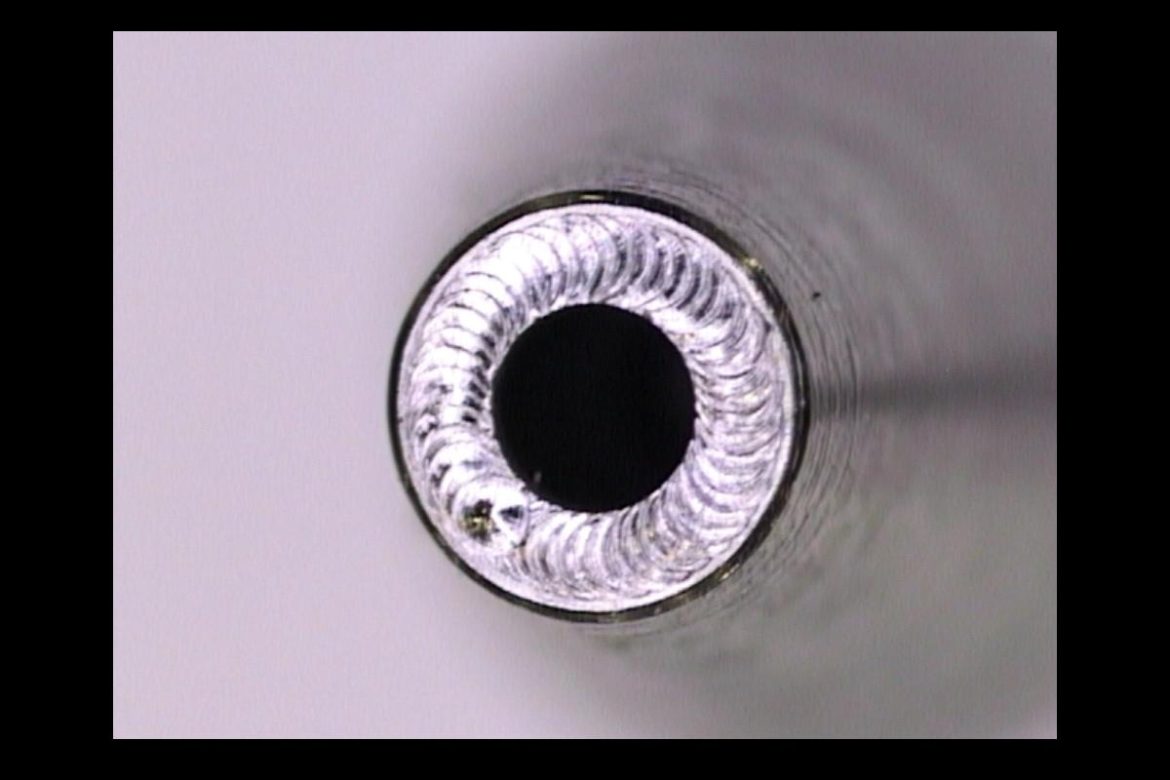

That’s where Medical Laser Welding earns its keep, where spot sizes around .005” aren’t marketing fluff; they’re what allow engineering intent to survive the trip from concept to physical reality. Where this technology quietly saves the day:

- Catheter-based systems where even a speck of excess material becomes a liability

- Tight-tolerance micro-sensors that punish anything short of perfect alignment

- Implantable modules shrinking year after year, leaving no room for clumsy joins

It’s not about forcing big tools into small spaces—it’s about working with a team that treats precision work as normal, not miraculous. That’s when innovation stops feeling fragile.

2. Advancing Biocompatible Manufacturing with Clean, Non-Contact Welding

Anyone building implantables or surgical instruments eventually hits the same wall: purity. It’s not glamorous, but it’s what makes or breaks regulatory pathways. You can design something brilliant, but if a joining method leaves residue, particulates, or anything that interferes with the body’s chemistry, the whole program wobbles. Micro laser welding, being clean and non-contact, avoids that headache altogether by taking fillers and flux right off the table.

This matters more in critical areas of quality control, ensuring biocompatibility and long-term device performance.

- Cardiac implantables that can’t afford invisible contaminants

- Reusable surgical tools facing thousands of sterilization cycles

- Ultra-sensitive biosensors that register contamination before anyone can see it

Here, Medical Welding becomes less of a fabrication step and more of a protective measure for everything downstream—your validation data, your inspections, your post-market confidence. The cleaner the process, the fewer surprises later.

3. Strengthening Device Longevity through Hermetic Micro-Sealed Enclosures

Moisture is patient, and electronics are stubbornly fragile in the wrong environment. For anyone working on implantable electronics, that battle is ongoing. The difference between a device that performs for a decade and one that fails prematurely often comes down to whether the enclosure was sealed with mechanical certainty—not “mostly sealed,” not “should be sealed.” Actually sealed.

Hence, outsourcing your micro laser welding needs to a reputable company like Micro Weld helps achieve guaranteed hermetic sealing through tight control of energy delivery to produce hermetic joints that stand up to the long game.

These are the areas where medical laser sealing pulls its weight:

- Pacemakers, neurostimulators, and closed-loop implants

- Telemetry modules whose electronics cannot meet moisture halfway

- Tiny housings where distortion can misalign the entire internal layout

Think of it less as a weld and more as a promise: the internal system stays untouched by the outside world. No guesswork, no hoping. Just protection engineered into the metal.

4. Protecting High-Sensitivity Alloys with Low-Distortion Welding Strategies

Working with materials like Nitinol or ultra-thin stainless steels feels less like machining and more like handling personality traits. They behave beautifully when respected—and disastrously when overheated or overstressed. Micro laser welding’s reduced heat-affected zone keeps those personalities intact, preserving the exact characteristics your team selected during R&D.

You see the impact of reduced heat-affected-zones especially in:

- Self-expanding stents, whose shape memory is non-negotiable

- Thin-walled hypotubes, where collapse equals scrap

- Orthopedic micro-components, where the geometry is the function

The process doesn’t force your material to “deal with it.” Instead, it adapts to the alloy’s physics so your engineering work doesn’t unravel during production.

5. Ensuring Regulatory-Ready Consistency Through CNC-Controlled Weld Validation

Everyone wants scalability; until they meet the documentation. Once you enter ISO 13485 territory, “repeatable” takes on an entirely new meaning. It’s not enough to weld beautifully once; the process has to hold that standard on unit number 3, unit number 300, and unit number 30,000. CNC-programmable micro laser welding makes this practical. It builds traceability, discipline, and predictability right into the workflow.

It proves its worth when you’re dealing with:

- Design verification builds where every weld must tell the same story

- Scale-up phases where inconsistency becomes financial bleed-through

- Post-market quality oversight, where documented stability matters

You don’t just get parts—you get proof. And that proof smooths audits, boosts investor confidence, and reduces regulatory friction.

6. Enabling Complex Architectures Through Dissimilar Metal Laser Joining

Modern medical devices rarely stick to one metal anymore. Sensors want one property, conductors want another, and long-term implants need corrosion resistance on top of it. Joining dissimilar metals without creating brittle zones or unwanted intermetallics is tricky—but pulsed laser welding with wavelength control makes it feasible, even elegant.

The core design challenges and specialized applications of advanced medical micro-welding and micro-joining technologies include;

- Lead systems blending conductivity with longevity

- Micro-sensor arrays that function across multiple material domains

- Hybrid implantables where each alloy plays a specific role

Instead of tightening design possibilities, this method widens them—letting your engineers think bigger without worrying about how to join materials that traditionally resist each other.

Ultimately, precision processes rarely steal the spotlight, but in medical device manufacturing, they quietly determine whether big ideas turn into reliable products. Microscopic laser welding supports that transformation—protecting repair integrity while enabling complexity, and reinforcing compliance. For teams committed to excellence, it becomes more than a technique—it becomes part of the strategy that carries innovation forward.